Join industry leaders who rely on puraDYN

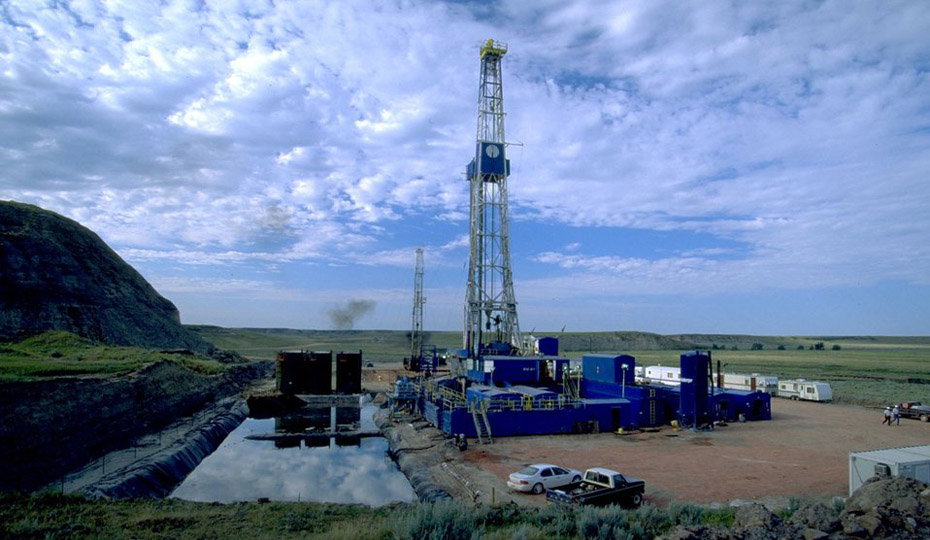

Upstream

Leaders in the oil & gas industry, including Nabors, Patterson, SWN and Scandrill, rely on puraDYN filtration to save them money from fewer oil changes, reduced maintenance, and longer engine life. In fact, puraDYN systems have been installed on the majority of U.S. onshore rigs, and many are experiencing oil life of over 5,000 hours (some report over 10,000 hours) thanks to their puraDYN systems.

More recently, companies have discovered the savings potential of equipping their pressure pumping fleets with puraDYN systems on their engines, transmissions and power-ends.

For more information, download our puraDYN Brochure for Pressure Pumping applications.

Midstream Segment / Pipelines

Pipeline operators use puraDYN systems on natural gas compressors, typically Waukesha and CAT engines, changing oil every four to six months of 24/7 operations with no maintenance issues. Due to the cleanliness of the engines and the efficient water removal through use of Puradyn‘s micro-fine filtration technology, they have also been able to extend engine overhauls by 10,000+ hours.

For more information, please download our puraDYN brochure for Midstream applications.

puraDYN systems work just as well to extend oil drain intervals on hydraulic systems which often cost more to maintain than engines.

Customer Testimonials

“Nabors’ use of puraDYN filtration systems to continuously clean engine oil has reduced our need for oil changes by over 80% and eliminated the need for most mid-cycle, top end engine overhauls.”

Siggi Meissner, President, Global Drilling & Engineering | Nabors Industries

“Installing puraDYN systems on our entire fleet is one of the most beneficial cost vs reward decisions I have made in my career to date.

We are not only saving money on oil by safely reducing oil changes, but more importantly, we now avoid losing 1-2 days per month of downtime to complete an oil change.”

Monte Madsen, Sr. VP | Legend Energy Services

“We have been able to safely extend our oil drain intervals to 5,000 hours from our previous practice of 1,000 hours. It’s a win-win for our customers, the environment, and Scandrill.”

Paul Mosvold | President & Chief Operating Officer | Scandrill

“Based on my prior experience with Puradyn, I am excited to equip the entire Campbell Transportation fleet with their oil filtration systems and safely reduce the frequency of oil changes on our engines and generators. Keeping our oil and engines cleaner will reduce downtime and maintenance costs for Campbell.” Michael Pilgrim, Manager of Vessel Maintenance | Campbell Transportation Company, Inc. | Houston, PA

“Puradyn offers the best solution for keeping engines clean, safely extending oil drain intervals and reducing overall life-cycle costs, protecting substantial investments in the commercial marine and industrial industries.” Harry Lartigue, Jr. | MnI Diesel | LLC Houston, TX

"It enables us to extend the oil drain intervals from our old standard of 250 hours to 3,000 hours. This equates to a savings of 354 gallons of oil or $3,210 per year. another boat in our fleet has been able to exceed 65,000 hours prior to overhaul." Captain Bill Clark | South Ferry Island | Shelter Island, NY

“While the puraDYN system quickly paid for itself by extending oil life to over 3,000 hours, its real value has been extending the life of our engines from running on continuously clean oil. It’s like an insurance policy for our engines.” Rocka Romcke | SuperYacht Captain

We calculate that we've saved over 60,000 gallons of oil. The engines remain clean and perform at peak level. We've also performed extensive fuel consumption measurements and consistently achieve a 2% - 3% savings in fuel."

Ross Hare | Hare Express, Inc. | Troy, M

Since 2010, Lima International Bus 1SA has utilized puraDYN filters on 81 articulated and 56 feeder buses. The articulated buses have been driven an average of 558,000 kms with oil change intervals extended to 78,000 kms while the feeder buses have been driven an average of 800,000 kms with oil change intervals extended to 132,000 kms. This represents an 86% reduction in the use of motor oil.

Jose Luis Diaz Leon | Lima International Bus 1SA | Lima, Peru

"...one of the most beneficial

cost vs reward decisions I have

made in my career to date."

Monte Madsen from Legend Energy Services

discusses installing puraDYN systems on their

entire fleet of pressure pumping engines.

Download our brochure

for the pressure pumping industry.